INSIGHTS & INDUSTRIES / WHITE PAPERS:

With the growing tension and increasing potential of conflict between global supply chain capitals, China and Taiwan, it’s now evident businesses, and indeed economies, must safeguard their logistics against disruption to ensure stability and growth.

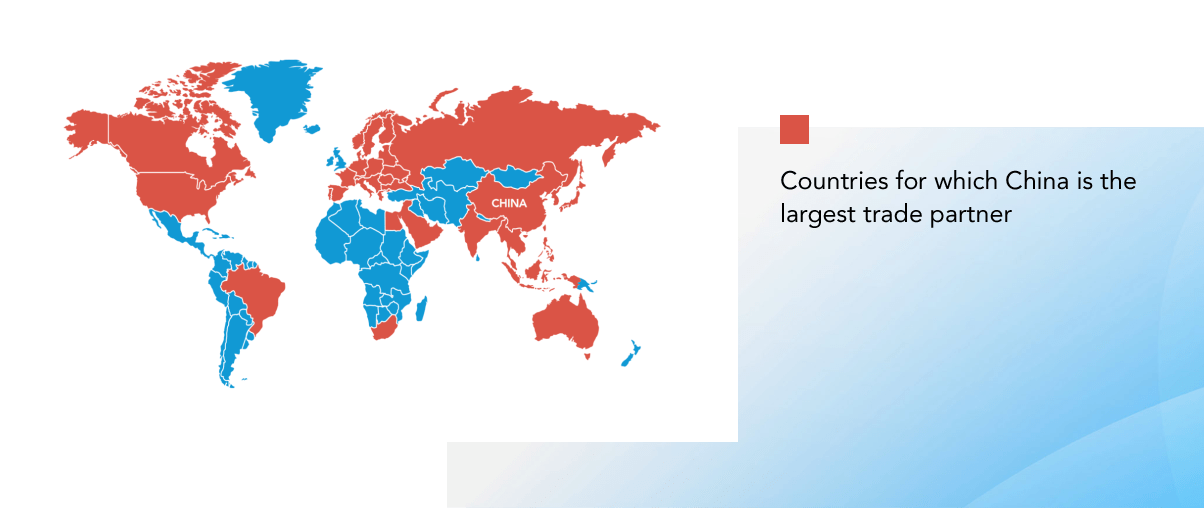

The risk of global disruption as a result of political tension, alongside the pandemic, has highlighted worldwide dependency on East Asia to sustain trade and supply across regions and industries. Further to this growing threat is the likelihood of decoupling, with strong indications regions may be moving toward segmented globalisation.

It has become apparent that, should businesses fail to protect themselves in an increasingly volatile and complicated global trade landscape, they risk the impacts of a compromised supply chain and threats to their long-term competitiveness and survival.

However, Australian business and government leaders are uniquely positioned to benefit from diversification of supply chains, in addition to consolidation of local manufacturing capabilities.

By playing to our collective competitive advantages, and critically, building technological capability, local leaders must explore strategies to overcome supply chain disruption. We discuss this landscape and look at the integration of ERP and AI as fundamental to drawing insights from the limitless variables that need to be considered in manufacturing and supply chain decision-making – paving a logical path towards true cloud-based business empowerment.

Australia has been aware of its dependence on China for some years now. Investors were moving away3 from China as early as 2020. Australia’s FDI (Foreign Direct Investment) more than halved in 2021, demonstrating the perceived risk of China’s presence. However, China is Australia’s sixth-largest foreign direct investor, contributing

$44 billion in 2020.

The dependency of Australia, alongside the rest of the world, on China was made painfully evident by COVID-19. Extended lockdowns in China caused significant supply chain turmoil. The recent lockdown imposed on Shanghai, the country’s economic powerhouse, saw a citywide lockdown for 60 days, from April to June in 2022, exacerbating already significant disruptions to global supply chains. will see the challenges already being faced on a much larger scale.

With the growing tension and increasing potential of conflict between global supply chain capitals, China and Taiwan, it’s now evident businesses, and indeed economies, must safeguard their logistics against disruption to ensure stability and growth.

Read More

In this white paper, we consolidated feedback from senior IT executives on why they switched from various SAP systems to NetSuite’s true cloud-based ERP, highlighting the pitfalls of fake cloud and on-premise deployments and how these challenges impacted their business.

Read More

This playbook looks at the trends driving modern smart manufacturers in a fast-paced, high-tech world and the need for a nimble, high-tech business system to match.

Read More